Checking Out the Advantages of Cane Sugar Handling Chemicals for Sustainable Practices

The assimilation of specialized processing chemicals in walking stick sugar production offers an engaging opportunity for advancing lasting techniques within the market. These chemicals not just enhance removal performance and item clearness however also add to considerable reductions in resource usage and ecological impact.

Introduction of Walking Stick Sugar Handling

Walking cane sugar processing includes a collection of complex steps developed to remove and fine-tune sucrose from sugarcane. This procedure starts with harvesting the sugarcane, which is commonly done by cutting the stalks short. sugar and cane. As soon as harvested, the walking stick is transferred to a processing facility, where it goes through shredding and cleaning to prepare it for juice removal

The following step entails crushing the shredded walking stick to release the juice, which contains liquified sucrose in addition to numerous impurities. This juice is then cleared up, usually via home heating and the addition of lime, to remove strong contaminations and get a clearer fluid. The made clear juice is ultimately evaporated to concentrate the sugar web content, resulting in a syrup.

Following evaporation, crystallization takes place, where sugar crystals create as the syrup cools down. These crystals are divided from the staying liquid through centrifugation. The raw sugar is more fine-tuned through procedures such as drying and washing, ultimately creating the last product that is appropriate for consumption. Each action in this extensive process is vital for ensuring top notch cane sugar, highlighting the intricacy and accuracy integral in sugar production.

Function of Handling Chemicals

The usage of processing chemicals is essential to the efficient removal and filtration of sucrose throughout walking cane sugar manufacturing. These chemicals offer multiple functions, including enhancing the clarity of juice, enhancing extraction rates, and assisting in the removal of contaminations. Secret handling chemicals include phosphoric acid, which helps in the explanation procedure, and calcium hydroxide, which neutralizes acidity and aids in the rainfall of pollutants.

In addition, processing chemicals can boost the general return of sugar by making sure optimum sucrose removal from the cane. Enzymatic therapies are also acquiring importance, as they can damage down complicated carbs right into fermentable sugars, thus raising performance. The application of these chemicals not only enhances the manufacturing procedures but also ensures that the resulting sugar meets rigid high quality criteria.

In addition, the function of processing chemicals reaches enhancing functional efficiency by minimizing the power and water needed during processing. This not just adds to cost savings however likewise aligns with wider sustainability objectives within the sugar sector. By maximizing the role and comprehending of these chemicals, makers can boost manufacturing efficiency while maintaining item top quality and security requirements.

Ecological Advantages

Lasting sugar manufacturing not just boosts operational effectiveness however likewise offers substantial ecological benefits that add to a much healthier ecological community. The usage of processing chemicals created for sustainability helps minimize the environmental footprint of sugar production. These chemicals frequently allow the decrease of damaging results, fostering a cleaner manufacturing procedure that safeguards neighborhood rivers and soil quality.

Furthermore, lasting techniques in walking cane sugar processing boost biodiversity. By minimizing chemical drainage and pollutants, these approaches guard habitats and advertise the health and wellness of bordering flora and animals. The application of environmentally friendly chemicals frequently brings about much better resource monitoring, as they can promote making use of natural waste products as plant foods, hence closing the nutrient loophole and enhancing the dirt.

Ultimately, these improvements not only sustain the sugar market's ecological goals yet likewise align with worldwide efforts intended at combating climate modification and advertising sustainability. Embracing these techniques is necessary for the lasting feasibility of sugar check over here production and the security of our world's sources.

Effectiveness and Waste Decrease

Implementing lasting methods not only boosts ecological results but also drives efficiency and waste decrease in cane sugar handling. The combination of specialized processing chemicals can dramatically enhance manufacturing process, minimizing the power and water intake usually connected with conventional techniques. For example, enzymes customized to boost sugar extraction can reduce the quantity of raw material needed, causing reduced operational prices and diminished waste generation.

Additionally, by utilizing naturally degradable or safe processing representatives, makers can minimize the risk of wastewater contamination, bring about reduced treatment requirements and additional saving resources (sugar and cane). Structured procedures allowed by these chemicals can additionally boost the recuperation rates of sugar, which not only maximizes output however additionally decreases the volume of spin-offs that require disposal

Additionally, executing real-time tracking innovations in combination with processing chemicals allows for better control over functional parameters, promoting quick modifications that can protect against inefficient deviations. Generally, the tactical use of walking stick sugar processing chemicals promotes an alternative technique to manufacturing performance, lining up financial feasibility with lasting practices that profit both manufacturers and the atmosphere.

Enhancing Item High Quality

Additionally, the application of pH regulatory authorities can enhance the processing conditions, ensuring that the sugar preserves its desirable taste profile while minimizing the development of unwanted spin-offs (sugar and cane). This not just boosts the overall high quality but also expands the service life of the sugar, meeting the demands of both retailers and consumers

Furthermore, the application of these chemicals is often lined up with sustainable techniques, minimizing the environmental effect of sugar manufacturing while improving item quality. By utilizing biodegradable and green processing representatives, manufacturers can boost their market charm and contribute to sustainable sector standards.

Conclusion

To conclude, the navigate to these guys integration of specialized walking cane sugar processing chemicals supplies considerable advantages for sustainable techniques within the industry. These chemicals not only boost juice quality and extraction go right here performance but likewise add to decreased energy and water intake. In addition, their usage minimizes hazardous results, thereby lowering greenhouse gas discharges and promoting environmental health. Inevitably, such green remedies align item high quality with sustainability goals, establishing a framework for accountable and efficient sugar manufacturing.

The combination of specialized processing chemicals in walking stick sugar production presents a compelling opportunity for advancing sustainable techniques within the market. Each step in this substantial process is important for making sure top quality walking stick sugar, highlighting the intricacy and accuracy intrinsic in sugar manufacturing.

The usage of handling chemicals is indispensable to the effective removal and filtration of sucrose during cane sugar production. The use of specialized handling chemicals can dramatically enhance the purity, color, and preference of sugar products.In verdict, the combination of specialized cane sugar handling chemicals provides significant benefits for lasting techniques within the industry.

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Robert Downey Jr. Then & Now!

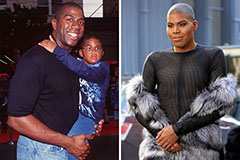

Robert Downey Jr. Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!